We are always proud of the fact that every DualLiner truck bed liner is made and manufactured right here in the USA. Over the years, we’ve gotten a lot of questions about how a bed liner is made, and so we decided to give our customers a peek inside our meticulous design and manufacturing process that ensures each DualLiner model we offer is the best bed liner available for the truck bed it is meant to protect. View our new video to see how we make DualLiner in the USA.

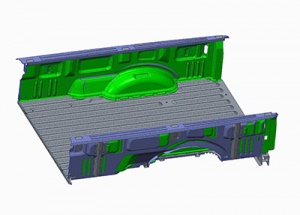

Through our partnerships with Ford, FCA-US, LLC (owner of Ram), and General Motors, we are provided with the exact CAD design files used to manufacture the actual body panels of the truck that we fit for a new DualLiner design. Using this digital model, we design a custom-fit second skin over the virtual panel with a channel along the bottom for our ZeroSkid™ rubber bed mat and provisions for model specific options such as bed lighting or tie-downs. Then we stress-test our model virtually and analyze the results to make sure it offers complete protection and exceptional durability.

We create a prototype tool from wood using our initial design.

Once our design is finalized and tested, we create a CNC wood mold to prototype our design and form the first few samples. With the precision of modern computer aided design systems, prototyping is usually not necessary, but we like to be sure our design is ready for production by taking the extra step for quality control.

The internal cooling lines ensure consistency and reduce the chance of warpage.

When the prototype is test fit and our design is finalized, we use the wood form to make a pressure-cast aluminum tool for full-scale production. This aluminum tool is cast with internal cooling lines and supports to help maintain proper temperature during production to ensure consistency in production. For the impact-resistant side panels of a DualLiner, we use High Density polyethylene with added UVA and UVB inhibitors to protect against damage from ultraviolet sunlight and create a finish resistant to fading, unlike other bed liners.

The impact-resistant sides are vacuum formed from utility-grade Polyethylene

Each sheet of polyethylene is loaded into our rotary thermoforming machine, heated in an oven until pliable, and then stretched over the aluminum tool for shaping. While it is stretched over the form, a vacuum removes any trapped air between the tool and the sheet and helps pull the sheet into the fine details of the tool.

A newly formed DualLiner ready for CNC trimming.

Once cool, the newly-molded bed liner is removed from the form and sent to a robotic CNC trimmer to remove excess material from the sheet and separate the two sides from each other. During this stage, the robotic trimmer also makes cutouts for tie-downs and bed lights.

The ZeroSkid rubber mat protects your bed from impacts and keeps your cargo in place.

The ZeroSkid® rubber bed mat is another unique feature of the DualLiner bed liner. Our heavy-duty rubber mat not only protects the bed floor but also holds your cargo in place so that it doesn’t crash into the sides of the bed while you’re driving unlike every other slippery drop-in bed liners. The mat is made using radial tire compress as our raw material with added recycled rubber “cake” to enhance pliability. We also add a nylacord mixture to improve durability and tensile strength. After the materials are combined, the rubber mixture is compressed into the mold for shape, then coated with a UV protectant when it cools for a rich black color and superior finish.

A completed DualLiner

From initial concept to production model, the process to make each DualLiner truck bed liner takes about six to eight months. Here at DualLiner, we believe that the time commitment to produce an extraordinary product is worth it. Compare DualLiner with other bed liner systems on the market today and you’ll see that nothing comes close to our commitment to quality and guaranteed perfect fit for the bed of your truck.

&

Click for Bedliner Comparison Chart>

I like this product very much. I’m going to buy it for my new F150 truck. My question is… do you make it in different color?

Best regards

Casey Trella